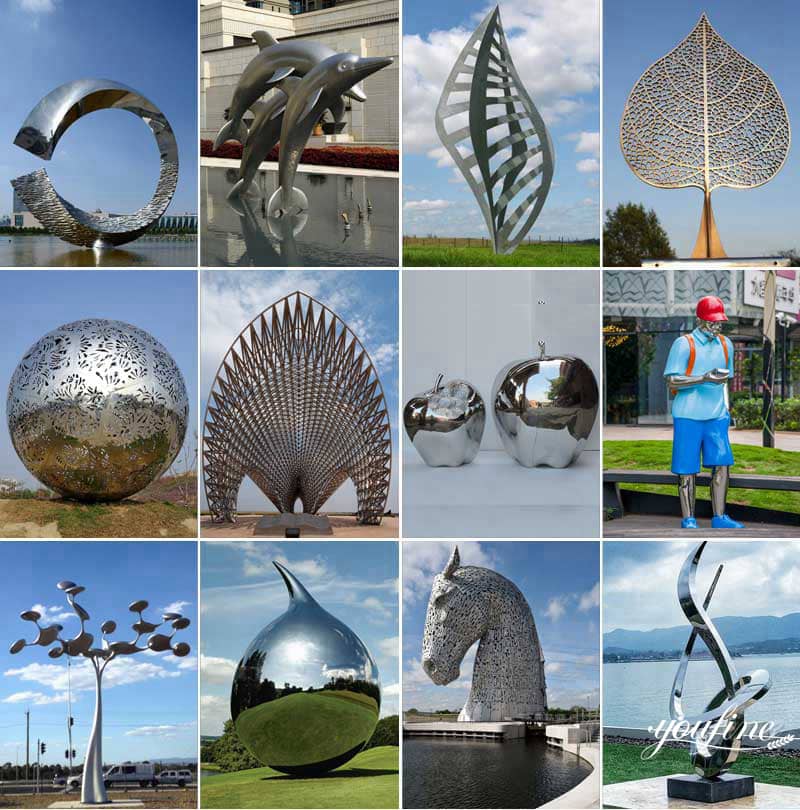

The contemporary urban decoration is inseparable from modern stainless steel sculpture. It can make the city more beautiful and the space more artistic. So, what is the production process of such an exquisite stainless steel sculpture?

-

Making of Skeleton or Model of the Modern Stainless Steel Sculpture:

Generally speaking, simple modern stainless steel sculptures only use the skeleton form of the sculpture. Under normal circumstances, calculate the required height and stainless steel sculpture model according to the proportion. The stainless steel tube and stainless steel flat steel are welded to form the inner frame of the sculpture. Then, the skeleton needs anti-rust treatment. It is to apply anti-rust paint three times on the frame. If the sculpture is a complex design, you need to replace the skeleton step with making a plaster model.

-

Cutting Stainless Steel Sheet:

This step is to cut out a suitable size stainless steel sheet according to the skeleton or model before the modern stainless steel sculpture. The general tool used is electric scissors. There is also a cutting machine, which could cut both thick and thin plates but could only cut straight lines, and there is nothing you could do when you encounter arcs. If you want to cut the stainless steel sheet into a flat shape and a variety of shapes, you must use a plasma cutting machine. The plasma cutting machine could use high plasma to cut metals that are difficult to cut by ordinary oxygen cutting. YouFine’s stainless steel sculptures generally require 304 stainless steel, and 316 plates are also used for high customer requirements.

-

Forged Stainless Steel Sheet Shape:

In this step, according to the shape of the modern stainless steel sculpture, the stainless steel sheet cut out in the second step is forged to a proper arc. According to the design and the different shapes of each part of the model, the material is discharged, and according to its fluctuations, it is consciously beaten. The bend is bent, and the edge is beaten. It could be performed on any tangible and strong object. Beat, and then take the knocked stainless steel plate to the mold for comparison, and think that the shape is correct and could be completely closed with the model.

-

Patch Stainless Steel Sheet:

Stick the stainless steel sheet successfully forged in the third step on the frame or model. The texture effect of the surface of each stainless steel plate must be kept the same, which must be forged at the same time as the shape is made. You could also forge the dots before cutting. When forging the points, use the round head of a hammer to forge evenly and regularly in rows, with the same width and narrow distance, and the same amount of force. Don’t knock it randomly, otherwise, it would destroy the overall sense of the sculpture.

-

Welding Together:

After the shapes are forged correctly, they must be welded together according to the requirements of the work (there are electric welding and argon arc welding). In this step, YouFine uses spot welding to determine the rough shape of the sculpture. After the prototype is confirmed, we would use the full welding method to weld each welding joint tightly.

-

Modern Stainless Steel Sculpture Surface Treatment:

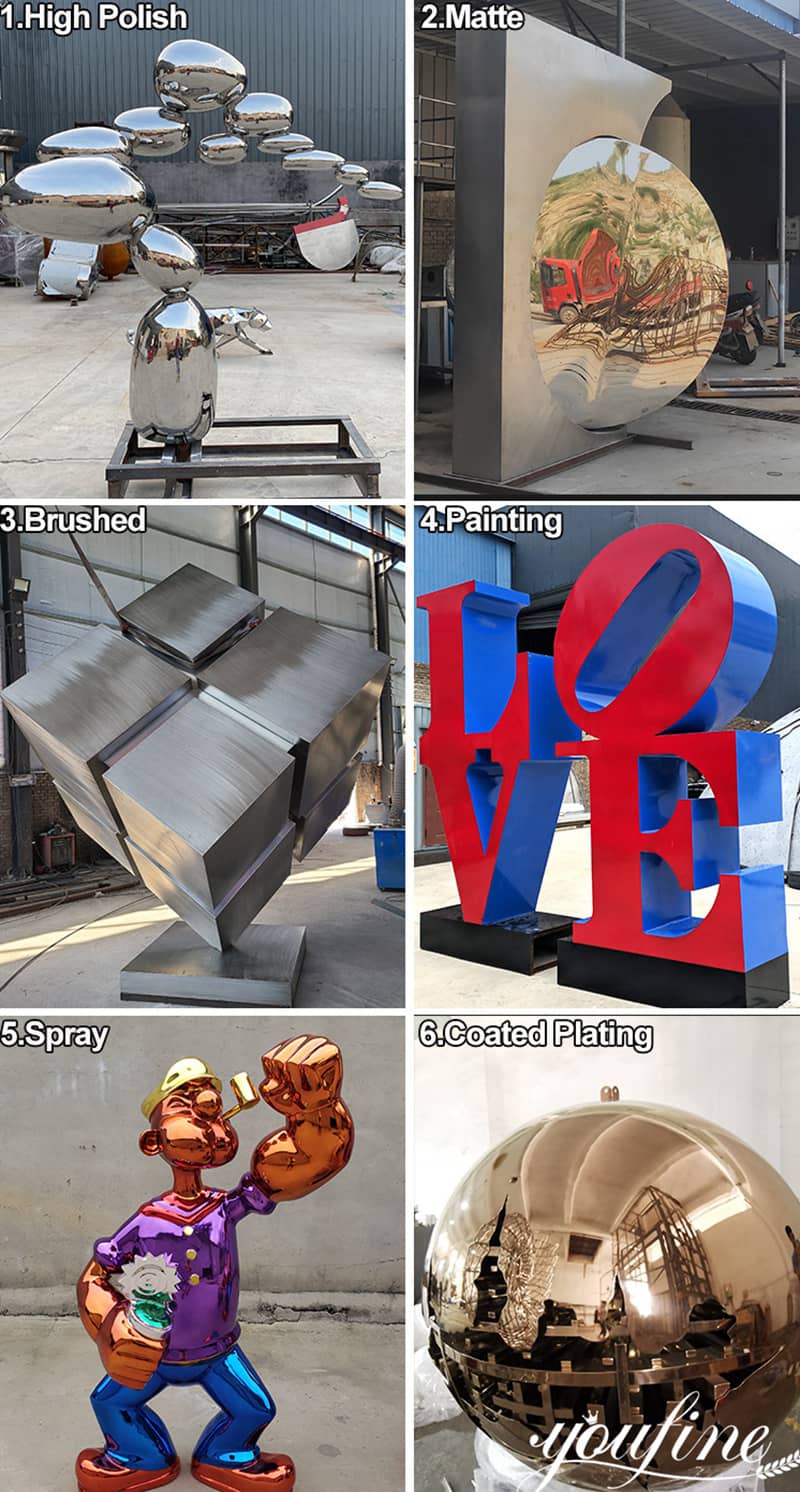

After the welding is completed, the surface of the sculpture should be polished. For stainless steel polishing. First, use a grinding wheel to smooth the welds and excess areas of the work. And then use a soft wheel (cloth wheel) for polishing. People have good visual beauty. After the polishing is completed, the surface of the sculpture would be processed according to the needs of the customer. Generally, there are many surface treatment methods such as high polishing, matte, wire drawing, spray paint, spray plating, electroplating, etc. to choose from.

After the surface treatment is completed, the exquisite modern stainless steel sculpture is completed in this way.