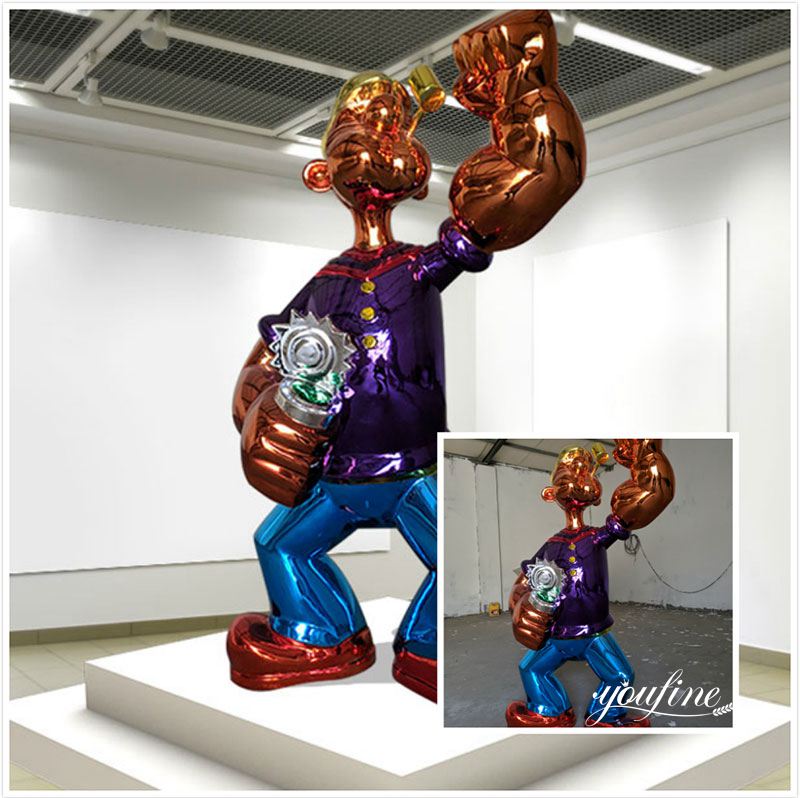

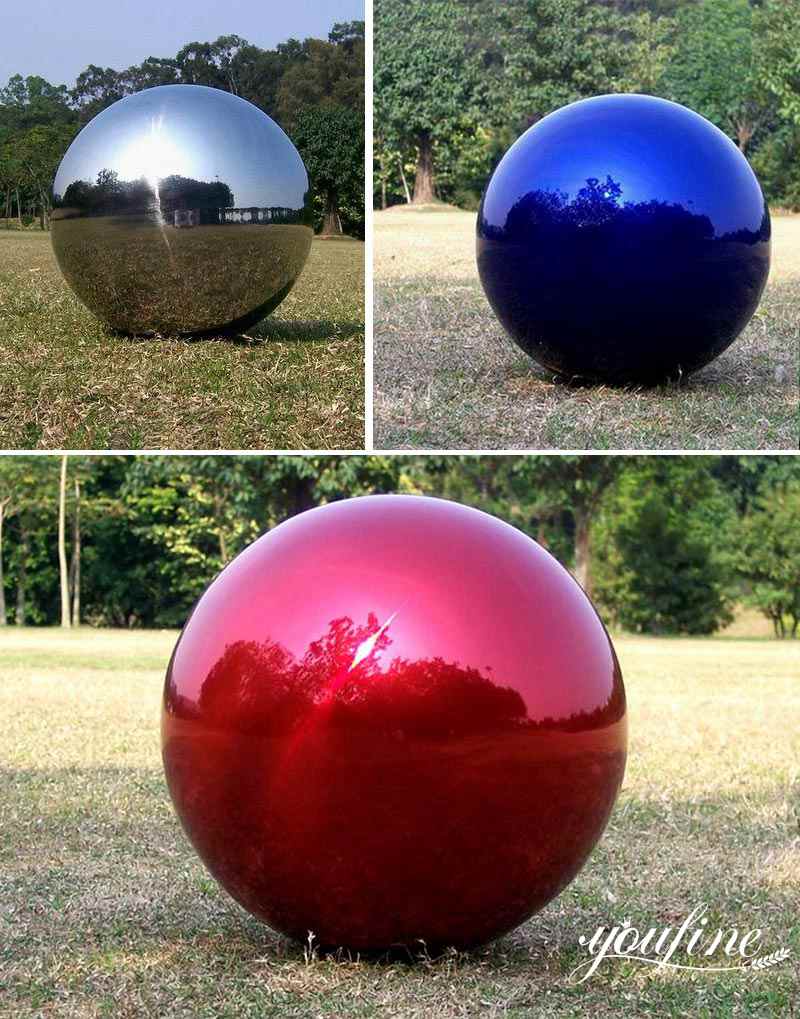

We could often see the exquisite colorful metal sculpture in some communities or parks. These sculptures greatly enrich our surrounding environment and give people a different sensory experience. Today, YouFine would introduce the sputtering process of stainless steel surfaces.

The Spraying of Stainless Steel Sculpture is Thermal Spraying:

The spraying of stainless steel is thermal spraying. Thermal spraying refers to spraying the surface of the stainless steel sculpture with the spraying material in the molten state and the power device. Thus the surface of the sculpture would form a complete covering layer. The heat sources commonly used in this technology are gas burning, electric heating, and lasers.

High-Tech Technology-Nano-Spraying:

Nano spraying is currently the most cutting-edge high-tech spraying technology in the world. This technology uses special equipment and advanced materials. And it applies chemical principles through direct spraying. In this way, the surface of the stainless steel sculpture presents various colors and exhibits various specular highlight effects.

The Benefits of Spraying:

The colorful metal sculpture sprayed by this technology has excellent adhesion and impact resistance. And the stainless steel sculpture is more corrosion-resistant and wear-resistant. Therefore, the sculpture has good anti-rust performance. More importantly, the process is simple and environmentally friendly. Nano-spraying has a wide range of uses and is a new surface treatment technology.

The Factors that Affect the Spraying Effect:

1. Oxide in the spray coating

When metal is sprayed on the surface of the stainless steel sculpture, the surface of the molten metal particles is hydrogenated to form an oxide film, which is mixed into the coating. Therefore, there is a considerable amount of oxide in the sprayed layer. If the oxide content is high, the sprayed layer would become embrittled and the adhesion would decrease. The oxide content varies with spraying conditions and methods. Therefore, we must pay special attention to the oxides in the sprayed layer.

2. The size of spray particles

The spray coating on the surface of the stainless steel sculpture is attached by the collision and irregular deformation of spray particles. When we observe the cross-section with a microscope, we could see that the particles become flat. And we could distinguish individual particles. Some particles are scattered due to the collision and formation of droplets. The size of the sprayed layer particles is not uniform. So it changes with the pressure of compressed air, spraying distance, melting temperature, and so on. The smaller the sprayed particles, the denser the sprayed layer and the better the adhesion. In order to obtain fine particles, YouFine pays great attention to controlling the spraying conditions.

3. Porosity

As mentioned above, the sprayed layer of sculpture is the collision, splashing, and deformation of sprayed particles. Then, the particles are attached to each other to form a plating layer. Therefore, there must be gaps between particles, resulting in porosity. This is the characteristic of spray coating. In addition, this porosity could also play a role in wear resistance and improve lubricity.

4. Adhesion

The adhesion between the spray coating and the surface of the sculpture is an important property of the spray coating. The reason why the spray coating could adhere to the surface of the sculpture is related to the convex and concave surface of the substrate. Therefore, the surface of the sculpture must be clean. In addition, the adhesion is also related to the spraying distance and gas pressure.

YouFine has mastered all the technical points of sputtering. The color of the YouFine metal sculpture is shiny, and the color is also very beautiful. Therefore, the surface of our sculpture is very beautiful. You could contact us immediately for more details on the effect of stainless steel surface treatment.

Tags: abstract outdoor sculpture, contemporary garden sculpture for sale, Stainless steel sculpture