What Is Stainless Steel?

Stainless steel, as the name suggests, is known for its corrosion resistance. Stainless steel is essentially a mild steel with added chromium. It is this addition of chromium in excess of 10.5% by weight that gives the steel its unique “stainless” corrosion-resistant properties. The chromium content of the steel allows the formation of a tough, adherent, invisible, corrosion-resistant chromium oxide film on the steel surface. If there is mechanical or chemical damage, the film is self-healing, provided oxygen is present, even in very small amounts. Corrosion resistance and other useful properties of steel are enhanced by increasing the chromium content and adding other elements such as molybdenum, nickel and nitrogen.

What Are the Grades of Stainless Steel?

Different grades of stainless steel are identified by the content of alloying elements. These affect their metallurgical Microstructure (specified type) as well as their mechanical properties and corrosion resistance, which could be exploited by engineers and architects. Although there are more than 100 grades of stainless steel, most fall into three main categories within the stainless steel family: Austenitic, Ferritic, And Martensitic.

Austenitic steels account for more than 70% of stainless steel production and are by far the largest proportion of stainless steels used in the building, building and construction market. The rest is mainly 430 grade ferrite.

Among them, 304 and 316 are the most suitable materials for making stainless steel. So we would talk about the detailed difference between 304 and 306 stainless steel here.

The Difference Between 304 And 316 Stainless Steel:

304 Stainless Steel:

Grade 304 stainless steel is not only rust resistant, but also strong and beautiful. Grade 304 stainless steel typically contains about 18% chromium and 9% nickel and is considered a general purpose stainless steel that is easy to machine, weldable and polished to a high gloss. With its chromium-nickel content and low carbon, Type 304 is the most versatile and versatile of the Austenitic stainless steels. Type 304 is proven to resist oxidation, corrosion and durability. All are easy to manufacture and clean, preventing product contamination and offering a variety of finishes and appearances. One area where 304 grade stainless steel does not work well is coastal environments. It is not very resistant to chlorides, and it is not always the best choice in high salinity environments. So if your stainless steel sculpture would be in a more ordinary environment, 304 stainless steel would be the best choice for cost performance.

316 Stainless Steel:

Type 316 stainless steel is an Austenitic chromium-nickel stainless steel and heat-resistant steel that has excellent corrosion resistance compared to other chromium-nickel steels when exposed to a variety of chemical corrosives such as seawater, brine solutions, etc. Since Type 316 stainless steel alloy contains molybdenum bearings, it has higher chemical resistance than Type 304. Model 316 is durable, easy to manufacture, clean, weld and polish. It is much more resistant to sulfuric acid, chloride, bromide, iodide and fatty acid solutions at high temperatures. If your stainless steel sculpture would be in some highly corrosive areas, then the best choice is 316 stainless steel.

In the difference between 304 and 316 stainless steel, price is also a very important part. In terms of material, even large stainless steel sculptures rarely use 316 stainless steel. First, because 316 stainless steel is nearly half the price of 304 stainless steel, and secondly, from the perspective of maintenance, although the corrosion resistance of 316 stainless steel is much better than that of 304 stainless steel, if it is not displayed on the seaside or in places with high humidity, 304 stainless steel would be used enough.

Although grade 316 stainless steel is a little more expensive than grade 304 stainless steel, grade 316 offers all the positive characteristics of grade 304, but with greatly enhanced corrosion resistance. Often referred to as “marine grade” stainless steel, grade 316 contains 18% chromium, 10% nickel, and most importantly 2% molybdenum. Harsh, salty environments in and around coastal areas and in chlorine-saturated areas near swimming pools would always present corrosion challenges to construction steel. While grade 316 may tarnish in the harshest locations over time, it is definitely the “go-to” stainless steel grade for railing projects around swimming pools and areas close to the coast. If budget allows, especially in New Zealand, we always recommend grade 316 as it provides the greatest corrosion resistance.

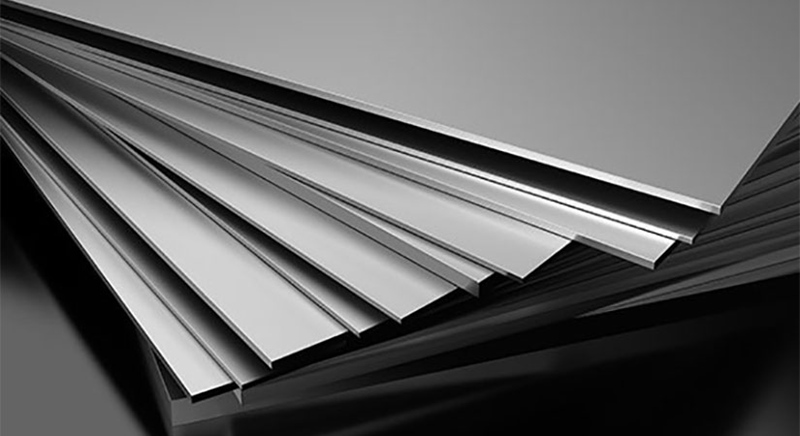

In terms of thickness, if the plate is too thin or too thick, it is not conducive to the implementation and completion of the stainless steel sculpture process. The thicker the plate, the less easy it is to shape, and the price is relatively high. If there are no special requirements, the thickness of stainless steel sculpture is generally 1.5mm, 2.0mm, 3.0mm.

Why Choose Stainless Steel As The Raw Material For Sculpture?

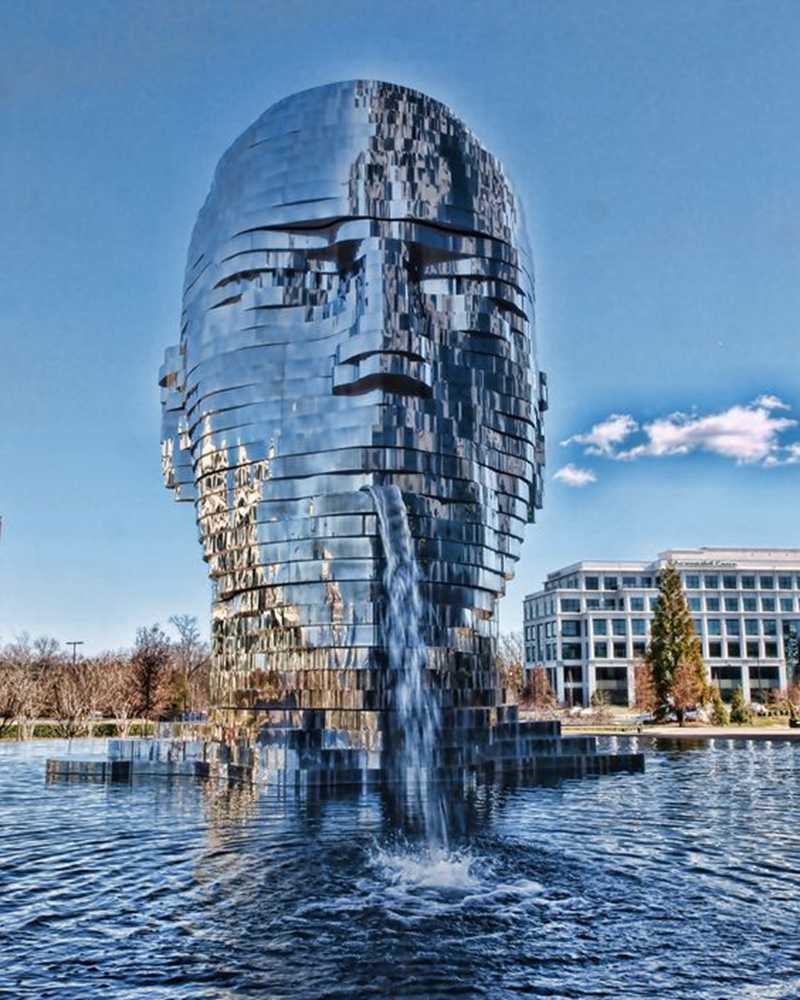

Stainless steel sculptures could be seen everywhere in modern society. They could not only express the beauty of modern art, but also have a long service life. These all come from their raw material – stainless steel. These are because stainless steel has good corrosion resistance, which makes stainless steel as a raw material for sculptures to keep the sculptures beautiful and clean for a long time outdoors. Moreover, the surface of stainless steel could be processed in various ways, which could satisfy many artists’ pursuit of art and beauty. Therefore, stainless steel sculptures are becoming more and more popular in modern times. And many of the world’s famous architectural landmarks are made of stainless steel.

Stainless steel sculptures made of different types and grades of stainless steel have different effects. If you have questions about the choice of sculpture material, you could contact us. Our professional business personnel would recommend the most suitable raw materials for stainless steel sculpture according to your different needs and the difference between 304 and 316 stainless steel.

Tags: Stainless steel sculpture, the Difference Between 304 and 316 Stainless Steel, What Is the Difference Between 304 and 316 Stainless Steel